Powder coating is a steadily growing industry, and with good reason! Powder coating provides many great advantages over traditional wet paint finishes, but is it the right fit for you? What exactly is the difference between wet paint and powder coating capabilities?

What is Powder Coating?

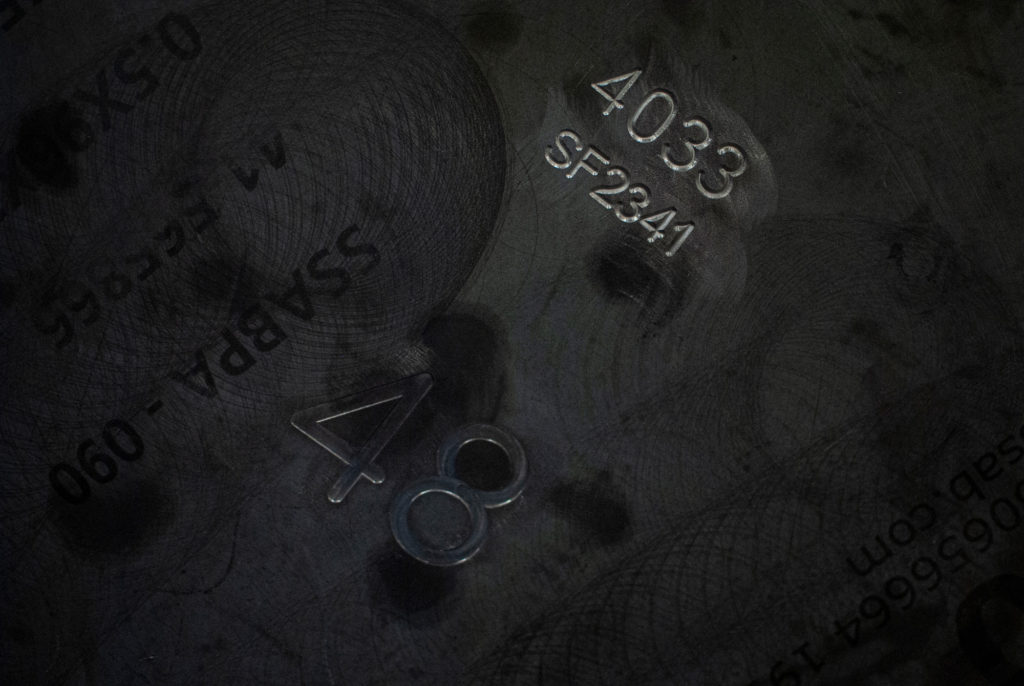

Unlike wet paint, which uses solvent to apply a finish, powder coating is applied as a type of polymer powder. This powder is adhered to a surface electrostatically, and is then heated in an oven to melt and cure the polymer into an even, finished coating.

Advantages of Powder Coating

Powder coating typically results in a much thicker, more durable finish than paint. This makes it an ideal choice for industrial equipment and automotive parts, as it is more fit to weather the wear and tear of the machinery. When the polymer powder is cured, the particles create long molecular chains which are stronger and more resilient than other finishes.

Because powder coating is applied electrostatically, it results in an even, blemish-free finish that shows no signs of drips, runs, or traces. Powder coating can also be done in a wide variety of textures and colors. In fact, here at Production Coating Specialties, we offer thousands of powder coating color options for you to choose from!

Powder coating is also a much more environmentally friendly option to consider. Since powder coating uses no solvent, exhaust air from the curing ovens generates minimal pollutants, and almost no harmful VOCs. Additionally, overspray in the application process can be collected and reused, further reducing waste. Among finishing techniques, powder coating is the greenest option available.

Lastly, powder coating has a much faster turnaround time. While paint can sometimes take days to dry fully, powder coating can cure in just 15-30 minutes. With two large ovens available, Production Coating Specialties can get your project finished and cured in no time flat.

Limitations of Powder Coating

Powder coating is a great alternative to wet paint, but does come with three main drawbacks. Firstly, powder coating is limited by its need to be heated and cured, making certain items inapplicable for the process. Certain wood or plastic materials may not be fit for powder coating if they cannot weather higher temperatures. Check with us here to see if your product is a good fit for powder coating!

The second drawback of powder coating lies in the application process. While the electrostatic technique makes for an even and durable coating, it is also somewhat thicker than wet paint coating. Attempting to apply a thinner layer of powder coating can result in an “orange peel” like texture that may be unsuitable for certain fine finishes.

Lastly, powder coating is a much more complex process than painting, and requires a variety of specialized equipment. Spray equipment, electrostatic booths, and ovens are all required for the powder coating process, which can be an arduous investment for smaller companies. Fortunately, Production Coating Specialties accommodates all needs, large or small! Since 2011, we’ve been providing expert service throughout Northern Minnesota for each step of the powder coating process.

Conclusion

Powder coating is a heavy duty finish option that is fast, environmentally aware, and high quality. With massive selections of color and texture to choose from, and an overwhelming durability standard, powder coating is a prime choice for recreational, industrial, automotive, manufactured parts, unique one-offs and large-scale production runs alike! While it may have a more limited scope of applications than wet paint, powder coating remains a strong and appealing alternative to all other finishing techniques.